Lithium iron manganese phosphate battery

Guoan Energy Technology (Dongguan) Co., Ltd. R&D Center Editor

a

I. Overview:

Olivine-type lithium manganese iron phosphate has the advantages of high energy density, low cost, and safety and stability, and has received widespread attention in lithium-ion battery applications. However, this material has the disadvantages of low electronic conductivity and manganese dissolution. This article elaborates on the current status of lithium-ion battery development, introduces the structure and performance of lithium manganese iron phosphate batteries, reviews its modification and preparation methods, and finally analyzes its industrial chain and application scenarios.

The energy density of lithium iron phosphate batteries can reach 161.27 W·h/kg. According to its theoretical specific capacity, the current energy density has almost reached its limit, so increasing the voltage platform is an important factor in further improving the energy density. Lithium manganese iron phosphate (LMFP) and lithium iron phosphate (LFP) materials have similar structures and comparable performance. Due to the high voltage characteristics of manganese, LMFP has a higher voltage platform than LFP, resulting in higher battery energy density.

II. Structure of Lithium Manganese Iron Phosphate Battery:

Because the ionic radii and physicochemical properties of Fe2+ and Mn2+ are similar, Fe can be used to replace Mn to obtain a stable and uniform solid solution LiMn1-xFexPO4 formed by LiMnPO4 and LiFePO4. LMFP and LFP both belong to the olivine structure, where P atoms form PO4 tetrahedra through strong P-O covalent bonds. These PO4 tetrahedra and FeO6 (MnO6) octahedra are cross-linked, limiting the change in lattice volume and ensuring high safety and stability.

The schematic diagram of the LiFePO4 structure is shown in Figure 1(a), and the schematic diagram of the LiMn1-xFexPO4 structure is shown in Figure 1(b).

III. Advantages and Disadvantages of Lithium Manganese Iron Phosphate Battery Performance:

The advantages of lithium manganese iron phosphate batteries compared to lithium iron phosphate batteries are:

(1) High energy density. The theoretical specific capacities of LMFP and LFP are similar, but LMFP has a higher voltage platform, so its energy density is about 10% - 20% higher than LFP;

(2) Good low-temperature discharge capacity. Studies have shown that at -20 ℃, the capacity utilization of the Fe platform accounts for about 50% of the Fe platform capacity, and the low-temperature capacity utilization of the Mn platform accounts for about 95% of the Mn platform capacity;

(3) Basically the same safety performance. The disadvantages are: (1) Poor conductivity. Lithium iron phosphate is a semiconductor, but after the addition of manganese elements, the band gap width is significantly reduced, resulting in LMFP having lower electronic conductivity and lithium-ion migration rate;

(2) Slightly worse room temperature cycle performance, and significant attenuation of manganese dissolution at high temperatures. Due to the Jahn-Teller effect, manganese ions may dissolve during charge and discharge, causing side reactions with the electrolyte and resulting in capacity loss. 。

Advantages of lithium manganese iron phosphate batteries compared to ternary lithium batteries:

(1) Improved safety performance. The olivine structure is more stable than the layered structure;

(2) Significantly reduced cost. Based on the average weekly price of raw materials from December 11-15, 2023 (the price of lithium carbonate is nearly 110,000 yuan per ton), the BOM cost per ton of NCM523, NCM811, lithium iron phosphate, and lithium manganese iron phosphate are 959,000 yuan, 1,139,000 yuan, 297,000 yuan, and 303,000 yuan, respectively;

(3) Longer theoretical cycle life.

Disadvantages:

(1) Lower energy density. The theoretical specific capacity of NCM materials is much greater than that of LMFP materials;

(2) Poor rate performance. The lower Li+ diffusion coefficient and electronic conductivity of LMFP batteries lead to poor rate performance during high-rate charge and discharge;

(3) Dual voltage platform: During the discharge process of the LMFP battery, Mn2+ is converted to Mn3+ near 4.1 V, and Fe2+ is converted to Fe3+ near 3.5 V, resulting in a dual voltage platform. The dual voltage platform may cause a certain power drop during the discharge process. Due to its structural characteristics, LMFP inherits the advantages of LFP, such as low cost and high safety, and compensates for its shortcomings such as low energy density and poor low-temperature stability. However, LMFP also has problems such as poor conductivity and manganese dissolution caused by the Jahn-Teller effect.

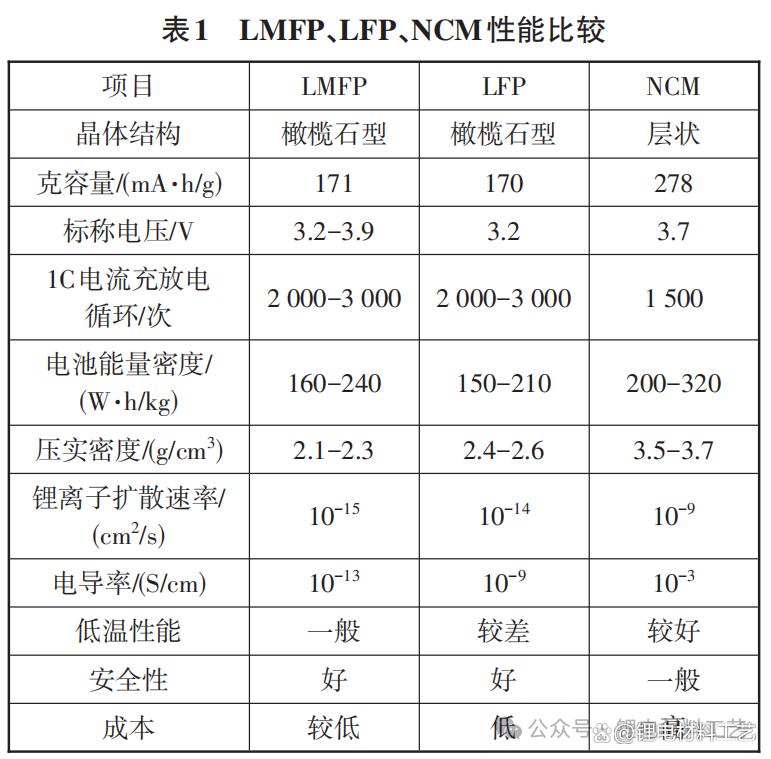

Table 1 shows a comparison of the performance of lithium manganese iron phosphate, lithium iron phosphate, and ternary lithium batteries.

IV. Modification Methods of Lithium Manganese Iron Phosphate

Currently, researchers at home and abroad use a combination of carbon coating + ion doping + nanometer modification strategies to solve the problems of lithium manganese iron phosphate materials. Carbon coating and nanometerization are commonly used modification methods for lithium iron phosphate materials to obtain better kinetic characteristics and improve rate performance. Ion doping is a unique modification strategy for lithium manganese iron phosphate materials, mainly used to suppress manganese dissolution and enhance ion diffusion, and one or more elements can be doped.

1. Carbon Coating

Carbon-containing organic matter is added to the precursor, and after co-firing, a nano-sized high-conductivity/high-ion diffusion uniform carbon layer is pyrolyzed on the surface of the material, thereby improving the electronic conductivity of the material; coating a uniform carbon layer can suppress the dissolution of manganese ions to a certain extent, thereby improving the cycle life of the material. However, the coating material needs to be in an appropriate amount. If it is too low, it cannot effectively improve the conductivity of the material; if it is too high, it will lengthen the lithium-ion migration path and hinder migration.

2. Ion Doping

A small amount of other elements (such as Mg, Co, Ni, etc., doping ratio is 0.01% - 0.1%) are doped into the crystal structure, creating vacancies in the material or changing the bond length between atoms, increasing the lithium-ion diffusion rate, and improving the battery conductivity.

3. Nanometerization

Control the size of cathode materials to nanoscale through mechanical ball milling and other methods, thereby shortening the lithium ion diffusion path, improving lithium ion conductivity, and enhancing its rate performance. Nanoscale particles can increase the specific surface area of the material, leading to better electrolyte wettability and reduced battery internal resistance.

V. Preparation Methods of Lithium Manganese Iron Phosphate

LMFP materials can be prepared by liquid-phase or solid-phase methods.

Liquid-phase methods include solvothermal method, sol-gel method, etc. Liquid-phase methods are conducive to controlling element ratios, resulting in better product consistency. However, products prepared by this method have low tap density and high unit investment. Liquid-phase production lines are similar to those for lithium iron phosphate and can be modified and upgraded, offering high compatibility.

Solid-phase methods include high-temperature solid-state method, carbothermal reduction method, etc. These methods are easy to industrialize on a large scale, have low unit investment, and high tap density, but it is difficult to control product consistency and particle size distribution. Among them, solid-phase methods share post-annealing equipment with lithium iron phosphate, but an additional iron-manganese mixing step is required in the front section. Compatibility depends on the process level.

VI. Lithium Manganese Iron Phosphate Industry Chain Layout and Application Scenarios

·Key companies in the lithium manganese iron phosphate battery sector include CATL, Sunwoda, BYD, EVE Energy, CALB, Gotion High-tech, Farasis Energy, etc.;

Material companies include Defang Nano, Ronbay Technology, Litai Lithium Energy, etc.;

Manganese source companies include Xiangtan Electrochemical, Hongxing Developing, etc.

LMFP matches NCM material voltage and can be used in combination to achieve products with good safety and energy density. Currently, CATL's mixed-use solution has been installed in Chery Luxeed S7 vehicles. CALB pioneered the OS high manganese iron lithium battery, with a system energy density of up to 180 Wh/kg and excellent battery performance. Gotion High-tech's L600 LMFP "Qichen" cell system energy density reaches 190 Wh/kg, with 4,000 cycles at room temperature. Tianneng Power's Lithium Manganese Iron Phosphate Battery TP-MAX has an energy density of 176 Wh/kg, and the product has been applied in Niu electric two-wheelers.

Currently, LMFP cells primarily have 3 technical routes, including pure use and two mixed-use technical routes.

The pure-use route is mainly for two-wheelers. Once the material matures, the cost per watt-hour is expected to be lower than LFP.

The high-manganese ratio mixed-use route mainly aims at LFP range upgrade, or LFP low-temperature performance improvement, filling the performance gap between high-nickel ternary lithium and pure lithium manganese iron phosphate, providing customers with more segmented and differentiated choices.

The low-manganese ratio mixed-use route primarily aims at NCM cost-reduction alternative solutions, capable of replacing low-voltage mid-nickel products, offering greater economic and safety advantages.

---Guoan Energy Technology (Dongguan) Co., Ltd. R&D Center Editor

Service Hotline

Email:zhangjie@ganeny.com

Website:www.ganeny.com

Address: No. 79, Shayuan Road, Shabu, Dalang Town, Dongguan City, Guangdong Province, China

Official Public Account

Privacy Policy | SEO | Support:300.cn